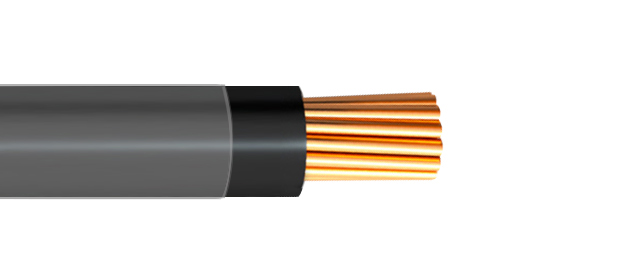

Wire and cable is a wire product that transmits electrical energy, electrical signals and realizes the conversion of electromagnetic energy. It is mainly composed of two parts: a cable core for transmitting electrical power or electrical signals and a sheath for protection and insulation. The wire core is generally made of copper metal with good electrical conductivity, and the sheath is generally made of plastic, rubber, nylon braiding and other materials.

What is the cable jacket

The cable sheath is the outermost layer of the cable, and acts as the most important barrier in the cable to protect the safety of the internal structure, protecting the cable from mechanical damage during and after installation. Cable jackets are not meant to replace the hardened armor inside the cable, but they can provide a fairly high level but limited means of protection. In addition, cable jackets provide protection from moisture, chemicals, UV rays, and ozone.

Types of cable sheaths

As the most important barrier of the wire, various materials of the cable sheath provide different protection. Here are some common high-quality sheath materials:

- PVC (polyvinyl chloride)

- It has stable physical and chemical properties, insoluble in water, alcohol, gasoline, low gas and water vapor leakage, strong chemical corrosion resistance, not easy to be corroded by acid and alkali, good mechanical strength and electrical insulation; the biggest feature is flame retardant ( The flame retardant value is above 40), so it is widely used in fire protection applications.

- PVC used to be the most widely used general-purpose plastic in the world. It is widely used in building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, fibers, etc.

- PE (polyethylene)

- It is odorless, non-toxic, feels like wax, has excellent low temperature resistance (the lowest operating temperature can reach -100~-70°C), good chemical stability, and can withstand most acids and alkalis (not resistant to oxidizing properties) acid). Because polyethylene is non-polar, it has low dielectric loss and high dielectric strength and excellent electrical properties. It can be used not only as frequency modulation insulating material, corona-resistant plastic, but also as high-voltage insulating material.

- Armored

- The armored cable mechanical protection layer can be added to the cable of any structure to increase the mechanical strength of the cable and improve the anti-corrosion ability. It is a wire and cable designed for areas that are vulnerable to mechanical damage and corrosion. It can be laid in any way, and it is more suitable for direct burial laying in rocky areas.

- In addition to the above, the purpose of adding an armor layer to the cable can also enhance mechanical protection such as tensile strength and compressive strength to prolong the service life. For transmission problems, the bending radius of the armor should be large, and the armor layer can be grounded to protect the cable.

- Nylon braided

- It is easy to pass through the pipe, and its excellent wear resistance reduces the damage to the insulation when the cable is passed through the pipe and laid, which can effectively reduce the hidden danger of latent short circuit accidents. It also has excellent resistance to oil, liquefied gas and gas corrosion, effectively improving To ensure the reliability and service life of the wires.

- It is easy to pass through the pipe, and its excellent wear resistance reduces the damage to the insulation when the cable is passed through the pipe and laid, which can effectively reduce the hidden danger of latent short circuit accidents. It also has excellent resistance to oil, liquefied gas and gas corrosion, effectively improving To ensure the reliability and service life of the wires.

- Nylon has a melting point of 215°C, high safety performance, the ability to withstand a considerable short-circuit current, and the same flame-retardant performance as PVC insulation.

The above are the most widely used sheath materials, and there are also PUR (polyurethane), TPE/TPR (thermoplastic elastomer), TPU (thermoplastic polyurethane rubber), etc. as sheath materials.

The sheath material plays a particularly important role in the cable, and is an important guarantee for the long-term safe and reliable operation of the cable product. Selecting materials with excellent properties and environmental friendliness can play the role of flame isolation, waterproof, insulation, corrosion resistance, high temperature resistance, etc., so as to maintain the integrity of the circuit and the smooth flow of power communication.